Technology Publication

Data Integration to Realize Industry 4.0 in Smart Manufacturing

02/01/2021 | No. TN054S-E_V1.0

High-Efficiency Production Management

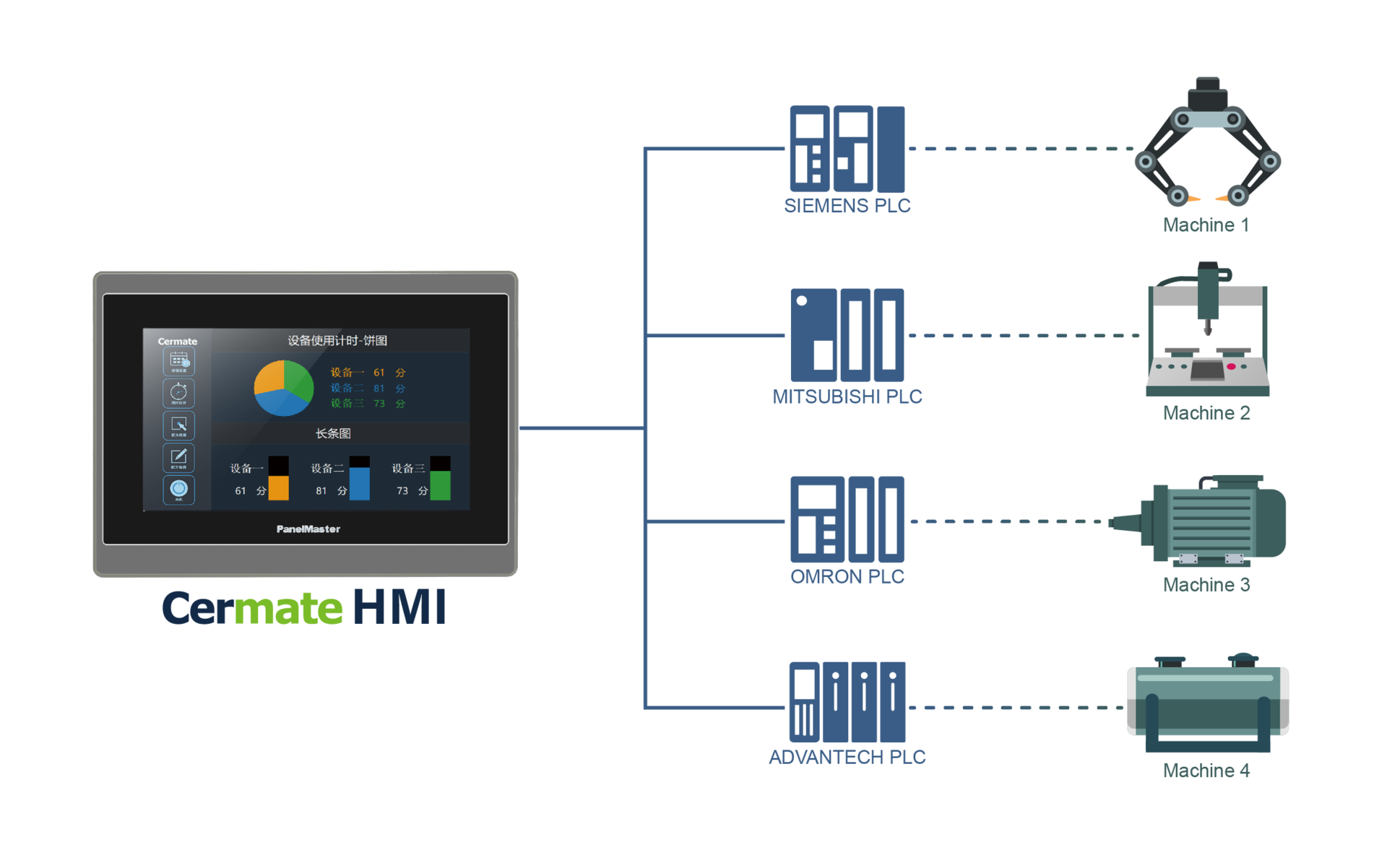

In factory automation, you have to use lots of protocol converters for equipment with different brand PLCs. It is a headache, and it takes a lot of time and money to plan and implement. Take an Assembly Area in a Production Line, for example, using machines with different brand PLCs performing various requirements. The biggest challenge is finding an intelligent device that can integrate and communicate with other protocols. Cermate HMIs, Edge Boxes, and PCs with PanelExpress support mainstream protocols. Machines are well managed and effectively communicate using our software with easy settings.

Optimized Flow in Data Integration

In Industry 4.0 trend, efficiency for operators and machines has a much higher priority. That means HMIs and Gateways are no longer simple-function operating devices. In a factory, you must have a data exchange center that can communicate and manage data from different PLCs among separate production lines. For example, when a motor demands a significant current that would lead to machine damage, an error code will be sent from the assembly area. It triggers the data exchange center to send error messages to the assembly area and stops the IQC and SMT area's process. Thus, it immediately avoids fatal damage to the production line. Use Cermate HMIs, Edge Boxes, and PCs with PanelExpress, which support mainstream protocols and data exchange functions, makes the manufacturing flow more intelligent.

Exchange Data for a Few Systems

Unique Feature in Data Exchange:

Exchange to another Network Are you still fighting with expensive and difficult network routers? Does the PLC need to get data from another network? Throw it away; now, you can simply publish data between two different networks.

(support model: two Ethernet ports IT series panel)

Extention feature “COV”; The new “Change on value” feature

When the system contains too many devices in the old design, the constantly poll and respond data will cause the communication data overflow. Besides exchanging data, we also develop a way to keep the data safe. We can now use the panel in any massive node among PLC systems without communication data overflow or lose any data due to communication blockage with COV feature. In other words, the panel does not always have to continually poll all the nodes one by one because the COV feature will significantly reduce the communication flow.

News

#Cermate Technologies Inc. #屏通科技股份有限公司 #屏通科技(上海)有限公司 #屏通科技(深圳)有限公司 #HMI #人機介面 #人机介面 #Panelmaster #Cermate #OEM #ODM #貼牌 #IIoT Gateway #物聯網 #閘道器 #网关 #ES Box #邊緣盒 #边缘盒 #IT400 #物联人机介面 #触摸屏 #IDCS #屏通雲聯服務 #屏通云聯服務 #IDCS Client #屏通云聯快訊 #屏通雲聯快訊 #HIH #HMI in Hand #屏通掌控 #PanelVision #屏通远见 #屏通遠見 #PanelExpress #屏通圖控 #屏通组态 #SCADA #The HMI Solutions and IIoT Gateways Provider. #人机解决方案 云联网服务

HMI (Human Machine Interface) 人機介面 触摸屏 工業物聯網 IIoT Edge Gateway 物聯網閘道器 物联网关 HMI Server HMI Client IDCS HiH 屏通掌控 PanelVision 屏通遠見 SCADA 圖控軟體 组态软件 PanelExpress Cermate Industrail Router

Previous Page

Previous Page